HENDI tray sealer is a modern device that is designed for use in catering establishments of all types.

The device is solidly constructed, made entirely of acid-resistant steel with a thickness of 2 mm a seamless construction allows quick cleaning of the lower body without having to turn off the device. Additionally backbone is insulated from high temperature and electrical voltage.

The sealing surface has special titanum coating, which prevents all types of film tape from sticking, and fast sealing in the 1-3 seconds. After using appropriate dies, the device has the ability to pack trays with a maximum dimension 235x190x(H)155 mm as well as mugs up to (H)170 mm.

Thanks to pressure shock absorber we have the possibility to adjust the pressure of the edge of the pack to the heating plate which prevents cracking of packaging, eliminates micro cracks and most importantly eliminates leaks.

Heater with high-powered heaters reduces warm-up time. Just 8-10 min to make the device fully operational.

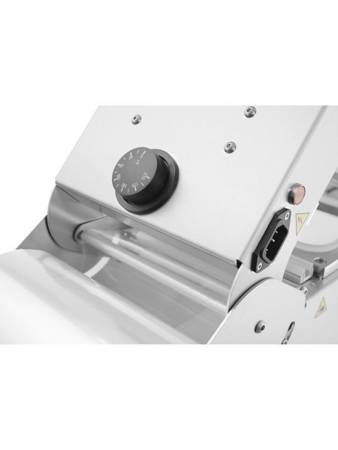

Uniform temperature over the entire sealing surface is precisely adjusted by a knob in the range of 50°C - 210°C and the applied thermal insulation reduces heat loss.

On the device you will find colored LEDs monitoring the operation of the device and illuminated safety switch. Inside, however, there is overheating interlock and overload fuse.

Our sealing machine has a special film feeder with a tensioner, which guarantees even alignment film and at the same time counteracts its curl. It will accommodate a roll with a maximum width of 187 mm and diameter 170 mm.

Product Features:

- Universal plate frame welding (all types of trays, including ecological trays, e.g. from sugar cane, paper pulp)

- Sturdy and stable stainless steel construction

- Lid with spring mechanism for easy and safe opening

- Welding process is almost effortless; resistance is minimal due to the use of bearings and special sliding material

- Pressure absorber ensures tight packing and prevents crushing of packages

- Non-heat-conductive pressure arm made of damage-resistant plastic

- Automatic retractable guillotine with safety knife in a specially designed sheath; cutting takes place just behind the sealed container in a special strip (air-cut technology)

- Film feeder with tensioner prevents film curling

- Outrigger guides with stops

- Sealing surface covered with special titanium coating, which prevents film from sticking and allows fast sealing in 1-3 seconds (depending on film thickness)

- High power heaters reduce heating time

- Warm-up time after start-up to full working readiness about 8-10 minutes

- Dial with precise control of welding temperature from 50°C - 210°C

- Colored LEDs to monitor the operation of the device

- Overheat lock, overload fuse, illuminated safety switch

- Non-slip feet stabilize the device during operation and protect the countertop from scratches

- Packing trays to a tray size of 235x190x(H)155 mm, and cups to a height of (H)170 mm

- Maximum roll size: width 187 mm, ø170 mm

- Device equipped with an aluminum alloy die for 227x178 mm containers, without division

- Power cord length of 1.5 m, grounded

- Net weight: 10 kg